Sign In / Sign Out

Navigation for Entire University

PV modules exposed to dusty environments like deserts, farms, etc. could see an accumulation of dirt on their front glass reducing transmittance, thereby causing a significant temporary performance loss. This could be reversed by cleaning the modules with any of the prescribed methods like air cleaning, brush assisted air cleaning and also using water. In arid environments, water is very scarce and an expensive resource to use frequently.

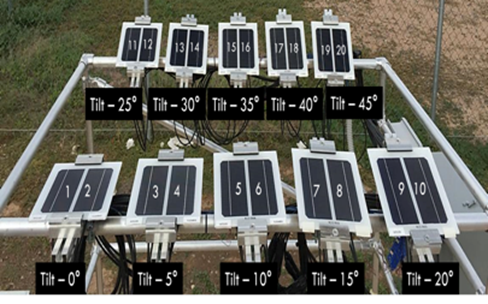

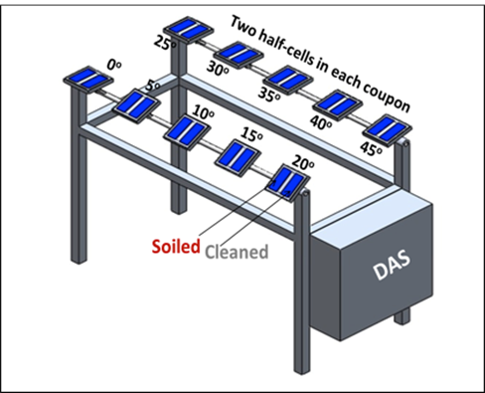

ASU-PRL has been working extensively on soiling by installing soiling monitoring stations across the United States (in collaboration with Sandia National Labs) and monitoring the influence of tilt angle on soiling loss, influence of soiling layer density and thickness on the angle of incidence, cleaning frequency, etc. The soiling station is equipped with a data acquisition system and 10 laminated coupons tilted at angles of 0°, 5°, 10°, 15°, 20°, 25°, 30°, 35°, 40°. Each coupon contains two identical half-cells cut from a single monocrystalline silicon cell. The right half-cell is periodically cleaned and left half-cell is allowed to soil naturally so the above stated data can be collected throughout the year. The construction of these coupons is identical to a commercial PV module containing solar glass, encapsulant, solar cell, encapsulant and backsheet. Each coupon (20cm x 20cm) consists of two half cells (15.6cm x 7.8cm each) which are coplanar to each other and separated by 1cm. The right side half-cell of each coupon is cleaned regularly, while the left side half-cell of each coupon is left to soil naturally. Each half-cell sensor is fitted with two durable cables and a durable junction box containing two precision low temperature coefficient current shunts (0.020 ohm each with TCR of ±20ppm/°C) between the positive and negative terminals of the cell. Short circuit current of each half cell is determined by measuring the voltage drop across the current shunt. The temperature of each half-cell is measured at the center of the backsheet using a T-type thermocouple.

Front view of the soiling monitoring station showing the different tilt angles of the sensors.

Soiling monitoring station cleaning.

Schematic diagram of a soiling monitoring station

Studies show that losses due to accumulated dirt on modules can reach as high as 15% for a period without rain. Apart from these losses, there are increasing number of claims of dust resistant coatings, abrasion resistant coatings (during cleaning), and new dust removal techniques. Currently, there is no standardized way of verifying the validity of such claims. As a first step towards validating such claims, a standardized artificial soiling method using a laminated module construction of glass/EVA/cell/EVA/backsheet is developed in this report. Also, the characterization tests that would give all-round information about the soiling losses are identified.

ASU-PRL has constructed an artificial chamber to maintain a controlled environment during soil deposition. The chamber consisted of a cuboidal mechanical structure to support an air bag from Sigma Aldrich Corporation. In order to avoid human errors, the spray gun with a lazer pointer is placed on a mechanical structure and the soil was sprayed. Soils were formulated artificially by mixing standardized soil or particulate matter, commonly referred to as AZ road dust (ISO 12103-1, A2 Fine Test Dust) with HPLC (High Performance Liquid Chromatography) grade acetonitrile. The distance between the test coupon and the tip of the gun was ensured to be about 2.5 feet.

Soiling Chamber.

The chamber is hermatically sealed to prevent any contamination.