Sign In / Sign Out

Navigation for Entire University

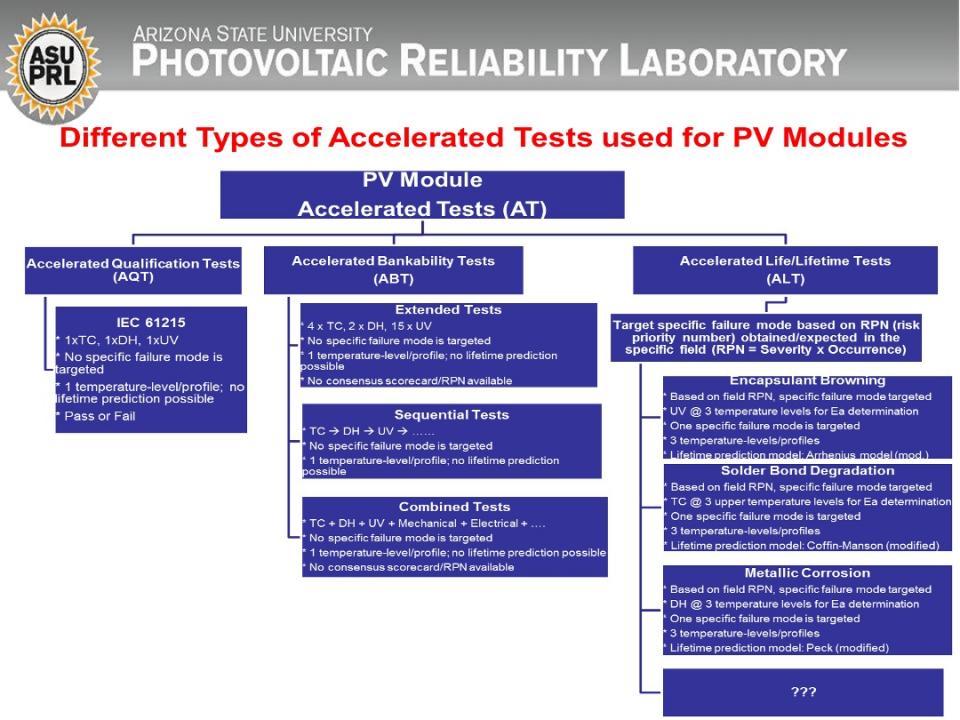

The life characteristics of a product including time-to-failure (TTF) are traditionally obtained using actual degradation field data. In the case of PV modules, the end of life (for example, time-to-degrade 20% from rated power) may be estimated using a simple linear extrapolation based on the annual field degradation rate (say, 0.8%Pmax drop per year). However, the manufacturers and the other stakeholders will have difficulty waiting long enough to obtain the degradation data in the field. The reasons for this difficulty include the very small annual degradation rate and the small time period between design and release. In AT, the product is forced to fail more quickly than it would under use conditions. The sole purpose of an AT program is to obtain life characteristics of the product being tested. In any AT, the general approach is to apply higher stress levels than actual use conditions over a short period of time to induce failures that would normally occur in the field. The AT can be used to induce both hard failures (reliability) and soft losses (durability or degradation).

Highly accelerated life testing (HALT) is a destructive test typically performed in the reliability/design laboratories of manufacturers during product development cycle. The purpose of this test is to find ultimate design weaknesses of the product. Highly accelerated stress screening (HASS) is a non-destructive stress test performed in the manufacturing screens/processes. The purpose of this test is to fail bad products that most likely will fail early in the field and pass good products. Failing units in both tests are subjected to root-cause analysis and corrective action. Both tests are done well beyond use/field levels and the failures are detected in a few months instead of after years/decades in the field. HALT and HASS tests may be performed under step testing mode with one environmental variable at a time (for example, temperature or UV light) or combined testing mode with multiple environmental variables at a time (for example, temperature and humidity). There is no single “standard or universal” procedure for the HALT or HASS test for PV modules, but multiple procedures may potentially be developed for various location/climate specific conditions.

The lifetime of PV modules is a function of a few key major field stresses such as temperature, humidity, UV light, and system voltage. The acceleration factor is the ratio between time in the field (or use) test and time in the accelerated test. The purpose of accelerated tests for PV modules is to shorten the test time using simulated test conditions much more severe than the actual field operating conditions but without altering actual field failure mechanisms. In the AT programs, the stress tests of PV modules are performed at higher levels than the field/use stress levels along with pre- and post-characterization of materials and modules from reliability, durability, and safety perspectives.

ASU-PRL has been conducting various experiments involving accellerated testing methods to predict the lifetime of PV modules and components for various stress conditions. ASU-PRL is well equipped to perform diverse accelerated tests with 3 large walk-in accellerated environmental chambers, a weatherometer, UV exposure chamber, and several small ovens for materials/coupon evaluation.

Walk-in environmental chambers to perform a variety of accellerated stress tests.

Weatherometer & ovens to perform accellerated stress test on coupons and components.

UV exposure chamber for PV modules and components.