Sign In / Sign Out

Navigation for Entire University

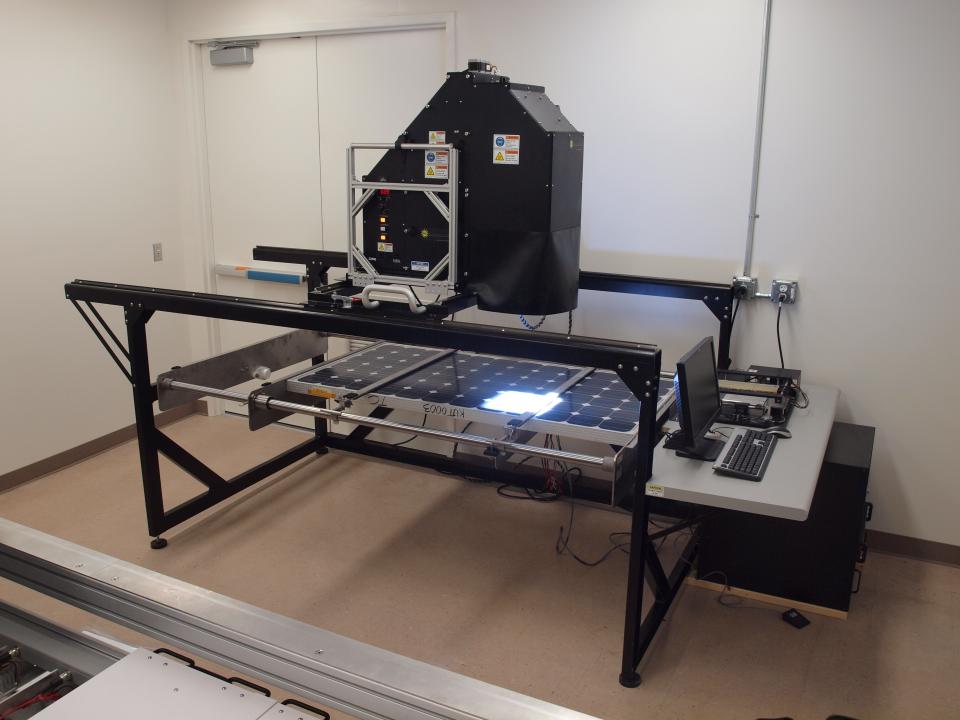

PV cell or module performance characterization reveals the degradation caused by the field or accellerated stress tests. ASU-PRL is equipped with a cell-module quantum efficiency (QE) machine, which is capable of measuring the QE of a particular region in a module non-destructively. This is extremely useful if the module has to undergo futher stress testing. In addition an indoor cell level IV machine with an integrated solar simulator helps in measuring individual cell performance in a module. ASU-PRL is also equipped with a number of IV curve tracers for characterizing cell, modules, or string performance.

Cell-Module quantum efficiency machine.

Cell IV machine with integrated solar simulator.

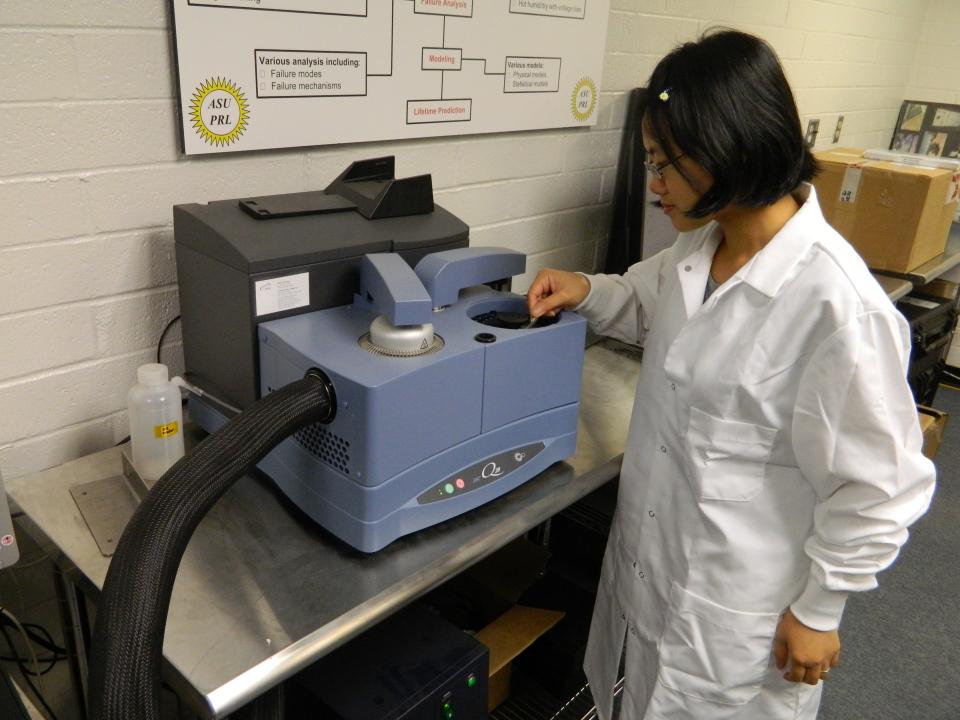

In order to continue dropping the price of solar modules down to goals and targets set by committees a large number of module manufacturers are currently using less or new materials in the design of a module. This includes making PV cell wafers and metallization thinner and . Because of this issue, encapsulants stability and protection are becoming an even more vital part of PV modules designs. As a module ages in the field and is exposed to a variety of environmental factors such as humidity, UV light, and temperature it degrades which can lead to changes in both the chemical and physical properties of the encapsulant. These changes affect both the performance of a module and the protection of the PV cells within a module. In order to increase a modules performance, reliability, and durability over its effective lifetime more understanding is needed in the field of PV module encapsulants and other polymeric materials in the module.

ASU-PRL is equipped with a host of material characterization equipment like FTIRs, spectral radiometers, differential scanning calorimeter, thermogravimetric analyzer and universal testing machine.

Differential scanning calorimeter

Spectral Radiometer measuring reflectance of a PV module to quantify encapsulant discoloration.

Encapsulant extraction for destructive material analysis.